The using life of the pattern conveyor belt will be affectd by which factors

2024-04-20 00:49In October of the previous year, our company shipped a 33-meter pattern conveyor with a width of 600mm and a pattern height of 15mm to a mine in Australia for coal mine transportation.

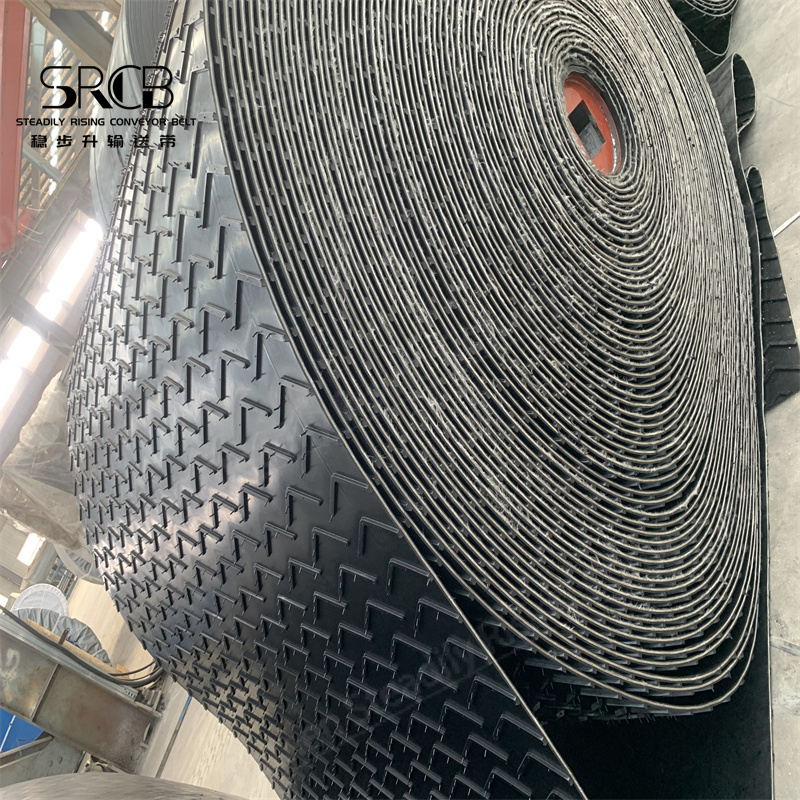

The patterned conveyor belt is an incline conveyor belt that made up of cover glue with pattern on the working surface and cover glue as the plane with the belt carcass on the nonworking surface. The pattern could be opened and closed, every pattern could be divided into three kinds of high, medium, low. It is applicable for powder, particles, transport small materials with the inclined angle less than 40 degrees. It can also conveyor bagged goods.

There are many types of pattern conveyor belt. Commonly pattern conveyor belt are diamond pattern conveyor belt, herringbone pattern conveyor belt, grass pattern conveyor belt, checkered pattern conveyor belt, etc. The conveyor belt enterprises introduced the type of pattern conveyor belt determines the using life of the conveyor belt. In the section of conveyor belt, it is necessary to assist in the selection of conveyor belt of conveyor belts if conditions permit, especially the type of pattern conveyor belt are many, it is more necessary for choosing carefully.

Design of conveyor, for the size of roller, transmission form, the conveyed method of equipment directly determine the using life of pattern conveyor belt. Pattern conveyor belt belongs to easy damaged part and it is one of the important parts of industrial production, so based on the properly choosing the pattern conveyor belt, maintenance of equipment is an important link.

Pattern conveyor belt is an inclined conveyor belt composed of pattern-shaped covering glue on the working surface, a flat covering glue on the non-working surface and a belt core. The surface of conveyor belt has a herringbone pattern that higher than belt body, the pattern could be open and closed, each type of pattern could be divided into high, medium, low. During the transportation and storage should keep clean, avoid the sunlight, rain and avoid to contact with acid and alkali, oil, organic substances that could affect the rubber quality and keep one meter distance from the heating equipment.

During the storage, pattern conveyor belt should be placed in a roll, it could not be folded, should be turned once a quarter. For reducing the impact and the wear of material to conveyor belt, the direction of materials should along the operation direction of conveyor belt; the gap between the materials that fall off to conveyor belt should be decreased; feeding port should be avoid the distance between rollers and take buffering measures. In order to prevent the tape from being scratched, the contact parts between the materials blocking device, scraper cleaning device, unloading device and the tape should be made of rubber with appropriate stiffness. Do not use tape head with a cloth layer sandwiched between them.