The conveyor belt enterprise introduce how many ways of installing defect and solutions

2024-04-10 00:44In March of the previous year, our company shipped a 45-meter conveyor belt with a bandwidth of 1000mm to a stone factory in the United States for the transmission and transportation of stone.

The conveyor belt is a mechanical device widely used in the industrial field. Its main functions include: material transportation,

material lifting, material accumulation, material classification, garbage cleaning, operating safety, and improving efficiency.

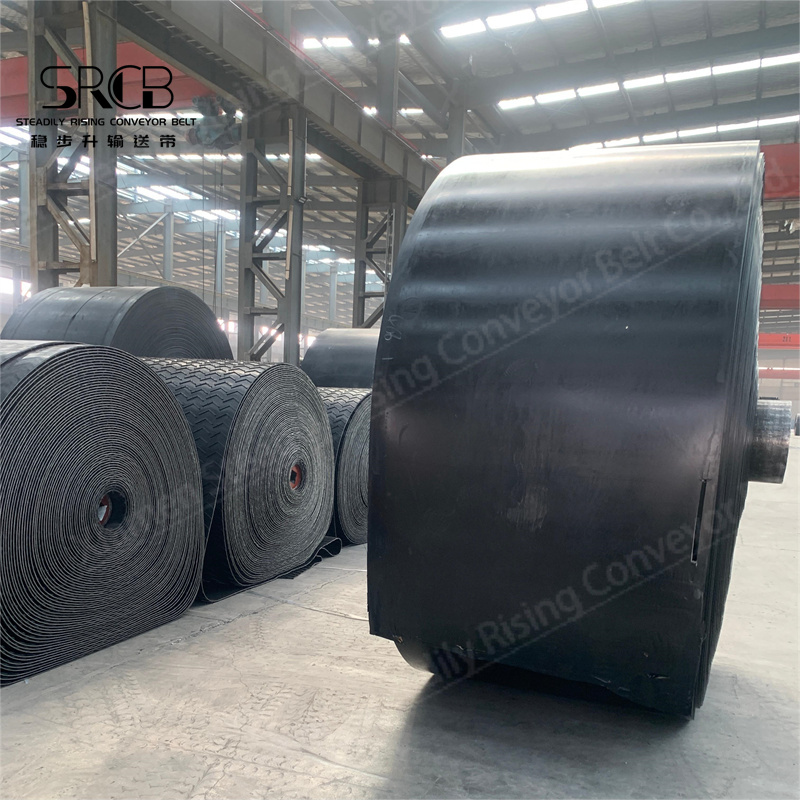

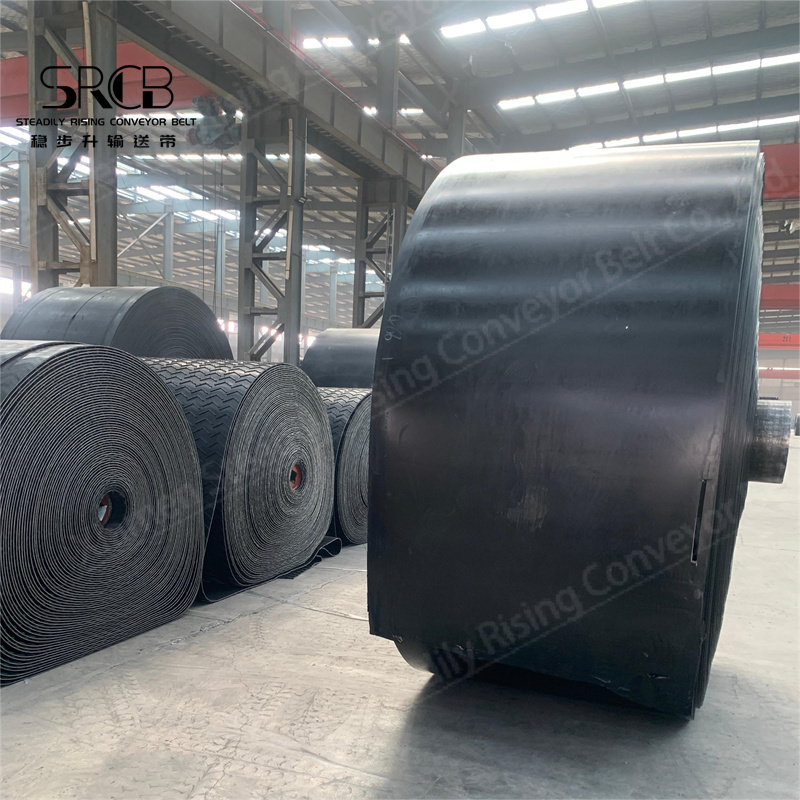

The enterprises of the conveyor belt introduced the conveyor belt that is made of multi-layer rubber cotton or polyester canvas covered with high temperature or heat resistant rubber which is bonded together by high temperature vulcanization that suits for conveying the hot coke, cement, slag, and hot castings, etc. that below 175°C. But, during the installation process it is usually to meet problems that hard to be solved. Today we will introduced some situations that you might encounter.

1. The welding quality is bad

The supervision of joint conveyor belt is very important in the installation process of the conveyor belt. Conveyor belt is made of muti-layer rubber cotton canvas or polyester covered with high temperature or heat resistant rubber which is bonded together with high temperature vulcanization that suits for conveying the hot coke, cement, slag, and hot castings, etc. that below 175°C. The quality of the joints will directly affect whether the conveyor belt will operate normally.

The quality problem of the vulcanized joint cause the broken belt accident occur from time to time, it not only affect the production but also resulting in personnel injury in some cases. Whether the quality of the joints is good or not will reflect on the result of use. If there is not strict control during the bonding process, it hard to find out the problem only depends on completion acceptance. Therefore, take the quality of the vulcanized joint seriously in the conveyor belt installation process is important.

2. No commissioning adjustments will be made after the installation is completed

Without running the equipment, new equipment are prone to generate wear partly. Especially pay attention to the adjustment of the funnel seasoning plate, skirt plate, baffle and other parts. Prevent the conveyor belt from deviating, jamming and other phenomena. In addition to reinforce the monitoring of the conveyor belt operation process to prevent large pieces of material from getting stuck and causing excessive wear of the conveyor belt.

3. The length of the conveyor belt device is not suitable.

Whatever the replacement of the newly equipment or the old, if carefully planning and the calculation is not carried out during the installation of the entire conveyor belt, it is easy to result in the situation of the conveyor belt to be extended. The direct result is the counterweight hits the ground lead to the start to slip. Although at that time is no problems and no problems during the test run, some of them were installed at low position. After many months, the counterweight sand and hit the ground when starting. It because during the installation process doesn’t consider in the elastic and the plastic deformation.