The strength standard of heat resistant conveyor belt

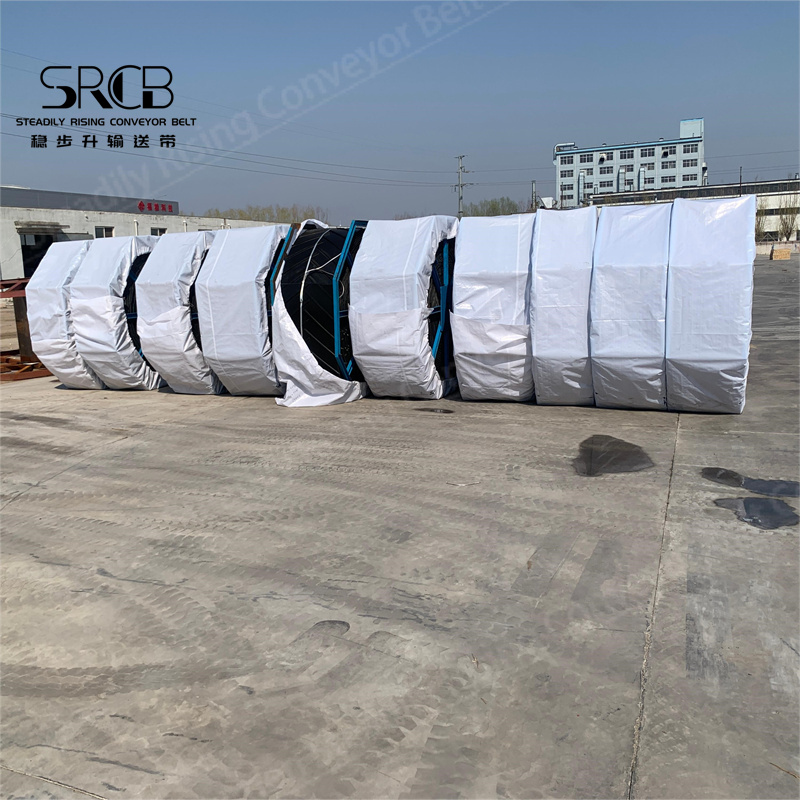

2024-05-15 09:56In February last year, our company shipped a 70-meter heat-resistant conveyor with a bandwidth of 1000mm to a coal mine in Australia for the transmission and transportation of mining materials.

The heat-resistant conveyor belt is made of multi-layer rubber cotton canvas (polyester cotton cloth) or polyester canvas covered with high temperature resistant or heat-resistant rubber, and is vulcanized and bonded together at high temperature.

It is suitable for conveying hot coke below 175℃. Cement, slag and hot castings, etc.

It is mainly used in metallurgy, construction and other industries to transport high-temperature materials such as sinter, coke, cement clinker, etc. The material temperature does not exceed 800°C and the belt surface temperature does not exceed 220°C.

The covered layer of the heat resistant conveyor belt: the tensile strength should not be less than 15MPA, the breaking elongation rate is greater than 350%, wear amount is not less than 200m3, the average bonding strength of the longitudinal sample layers are greater than the cloth layer, the average inter layer bonding strength between the covered glue and the layer should not be less than 10%, the longitudinal reference force elongation of the full thickness

Is should not be greater than 4%, the skeleton of the nation standard tensile strength resistant coefficient could be built ring.

Adjusting the deviation of the conveyor belt: the idle speed is normal, add the deviation of loading, this might be the material’s landing point is not in the middle of the conveyor belt, the distribution is biased to one side, under the action of eccentric force makes the conveyor belt to deflect. Changing the position or structure of the blanking gate baffle so that the blanking material is located in the middle of the conveyor belt. When idling, the operation deviation is weaken or normal after feeding. Which is caused by the belt is too loosen or the excessive initial tension.

When the tension is too high, conveyor belt will jump off from the rollers, produce the floating swings; the tension is too small will reduce the friction between the roller and the conveyor belt, reduce the power of forward longitudinally and reducing the lateral movement of the conveyor belt that causing deflection. Solving it by appropriately increasing or decreasing the gravity. When the belt conveyor has spiral tension or hydraulic tension, it could be solved by adjusting the tension stroke.

When vertical error between the installation position of the conveyor belt and the central bank of the belt conveyor is large, the idling speed is not parallel to the running speed of the conveyor belt that could be divided into horizontal speed and the longitudinal speed. The horizontal speed will drive the horizontal movement of the conveyor belt, longitudinal speed makes the conveyor belt to move transversely causing deviation. Deviation direction is related to the inclined position of bearing roller groups. This could be eliminated by adjusting the position of roller or installing a centering roller set.

When the center line of head shaft drive roller or the tail of steering roller can not be perpendicular to the conveyor causing the roller to deflect, the tightness of the both sides roller on the conveyor belt is inconsistent, the traction is inconsistent along the width direction. Therefor, conveyor belt moves to the tight side and deviates. The front and rear position of the roller bearing seat is adjustable. If the head roller deviates to the right, the right bearing seat will move forward; if the head roller deviates to the left, the left bearing seat will move forward. The adjustment methods of the tail roller is opposite to the adjustment of the head roller. When the deviates is seriously the racks need to be reinstalled.