Considering which selected factors when choose the conveyor belt

2024-04-08 00:31In January of the previous year, our company shipped a 25-meter conveyor with a bandwidth of 800mm to a logistics field in Kenya for the transmission and delivery of packages.

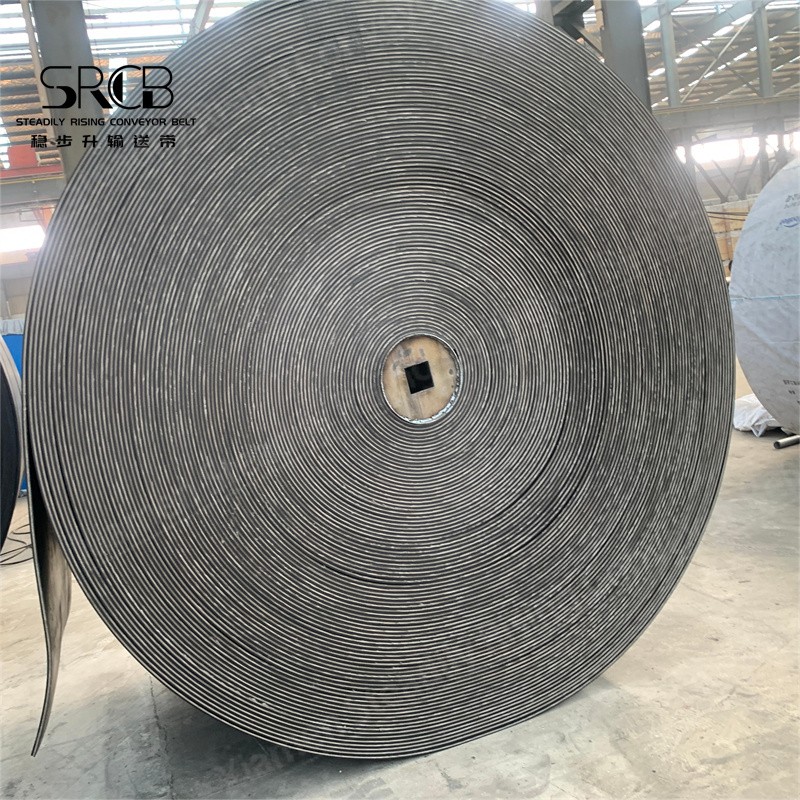

The conveyor belt is a mechanical device widely used in the industrial field. Its main functions include: material transportation,

material lifting, material accumulation, material classification, garbage cleaning, operating safety, and improving efficiency.

With the development of the industry, machinery is constantly optimized, and the number of manufacturers of the conveyor belt in the market is growth. It has advantages and disadvantages for the customers; the advantages is that the customer will have more choice of conveyor belt manufacturer. Disadvantages is that there are too many companies and people are dazzled, they have no idea of choosing which one is good, that often to choose wrong one.

1. When choosing the conveyor belt, it depends on the using environment, heat resistance , cold resistance, oil resistance and acid alkali resistance the thickness of the conveyor belt surface shouldn’t below 4.5mm, the thickness of upper and lower cover glue should be the multiple of 1.5. According to the cargo weight to choose. Because of the different structure of the material, the conveyor belt will have different capacity to carry the weight of cargo. So, when we choose the conveyor belt should choose the belt with a relatively larger carrying capacity.

2. Depends on the using environment. If is the type of goods, when selecting the conveyor belt that is appropriate for cargo type, consider the different of designing material of conveyor belt which decides the different of the type of goods when transported, such as the flammable goods should select the flame retardant conveyor belt with its high strength, large transportation capacity, conveyor stably and other features. At the same time, it has good flame retardant resistance, anti static, anti impact resistance, corrosion resistance and other properties.

3. Selected according to the rate of conveying. The running speed of the conveyor belt is generally not be greater than 2.5m/s, for materials with large lumps, high wear resistance should adopt low speed to use the fixed unloading equipment. Therefore, choose the conveyor belt that suits for the requirements according to the speed of the machine. When choosing the conveyor belt there are a lot of skills that need we continuous practice and improvement ensure the selected conveyor belt could satisfy our needs。

4. The product itself has the characteristics of anti static, water proof, flame retardant, high strength and the cost compare with other flame retardant will be lower and the price is lower too. It is a commonly type of conveyor belt that used in the domestic or abroad, popular of the mining. It especially suitable for the conveying places with small slopes in coal mines and other underground mines. It uses the whole belt core as the skeleton material, is impregnated and coated with PVC materials with good anti static, flame retardant resistance and other properties.

5. The performance of welding: According to the strength of the belt and the core structure of the belt, using the mechanical belt buckle to connect its strength can reach 50%-90% of the belt body strength; using the vulcanized joints its strength could reach 60%-90% of the belt body strength, multiple forms of joints could satisfy the different requirements of the guests, make sure the operation of the system.