Steep inclined conveyor belt

2024-01-22 18:00Last year, our company shipped a 20-meter high-angle conveyor belt with a bandwidth of 1200mm to a coal mine in the United States for the transmission and transportation of mining materials.

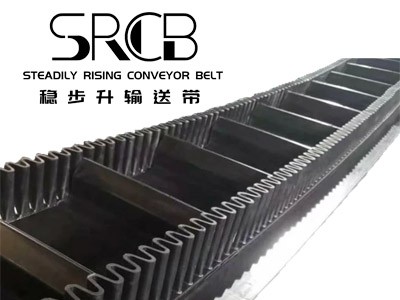

The high-angle corrugated sidewall belt consists of three parts: base belt, sidewall, and diaphragm. The ribs prevent materials from slipping and falling. In order to make it easier to bypass the roller, the ribs are designed in a corrugated shape; the function of the diaphragm is to support the material. In order to achieve large-angle conveying, a T-type TC type is adopted. The ribs and diaphragms are connected to the base belt by secondary vulcanization, which has high connection strength. High-angle conveyor belts are mainly used for horizontal transportation of bulk materials such as coal, coke, sand and gravel, and can also be used for vertical transportation of finished items.

The steep inclined conveyor belt is a device used for material transportation at a large angle(above 30 degrees). It has excellent transportation capacity, occupy small space, saving manpower and materials and it is applied for many places such as in mining, electric power, metallurgy, chemical industry and other fields. When we choosing the steep inclined conveyor belt we should take care of the following aspects.

First of all, we should consider the nature of the conveyor belts. Due to different materials have different physical and chemical properties. Thus, when we choosing the high angle conveyor belt we should think about the particle of size, humidity, abrasion and the viscosity of the material. Some high humidity and viscosity may require the belts with special coating to prevent some materials during the conveyor time that adhering to the belts that affect the conveying effect.

Secondly, the angle of the conveying need to be considered. The steep inclined conveyor belt is able to conveyor materials at a large angle but different conveyor belt has different conveyor range angles. Usually, the larger the belt angle is, the better the conveying capacity is. But it will increase the price of the equipment. So, when we choosing the high steep conveyor belt we should make sure the appropriate conveyor angle according to the needs.

Thirdly, we should think about the conveyor distance and the conveyor capacity. The conveying capacity of the steep inclined conveyor belt influenced by the speed of the conveyor belts, the width of the conveyor belts, the conveying angle. Hence, the time we choose the steep inclined conveyor belt should according to the conveying volume and the conveying distance to determine whether it is suitable for width of the belt and the speed of the belt or not. At the same time, we should consider the load capacity of the conveyor belt and make sure it could stand the weight of the materials.

In addition, when we selecting the conveyor belt we should think the wear and the corrosion resistance. During the conveying period the inclined conveyor belt might get impacted and worn. So we need to choose the belts with higher wear resistance. At the same time, if the belt conveyor some corrosive materials, we need to choose a belt with good corrosion belt to extend the using life of the equipment.

After that, we should give a think to the layout of the whole equipment and the maintenance. Steep inclined conveyor belt need to occupy a relatively large space and the components such as the roller and the driving devices need to be installed in the inclined section. Therefore, we should place the equipment appropriately according to the actual needs of factory or the mine. And we should think the daily maintenance of the equipment, choose straps and parts that are easy to maintain and replace to reduce equipment failure and downtime.