The selection of flame retardant conveyor belt and use precautions

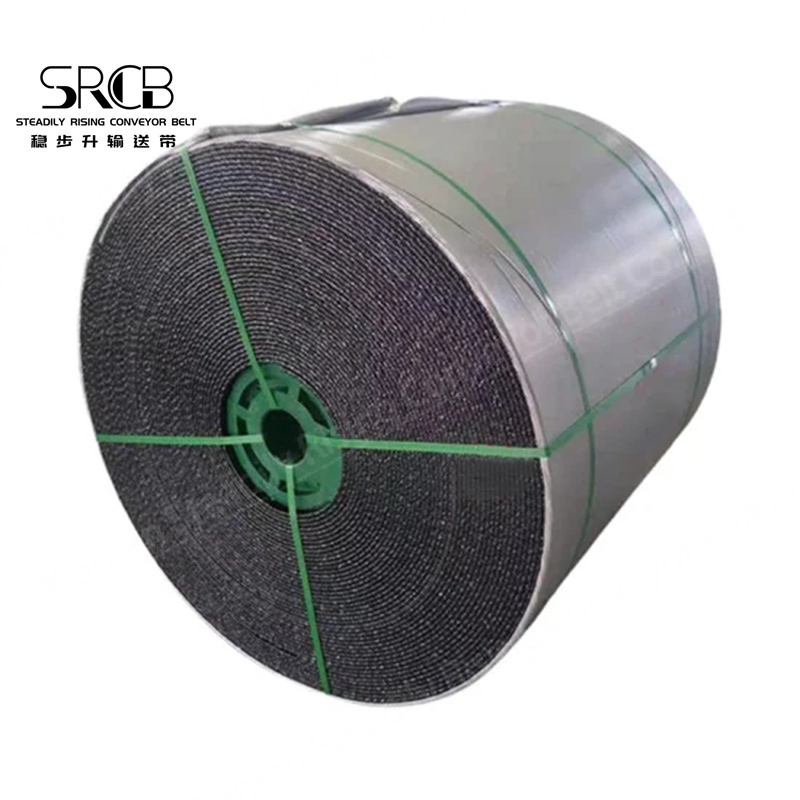

2024-05-20 16:44At the end of June last year, our company shipped a 96-meter flame-retardant conveyor belt with a bandwidth of 800mm to a coal mine in South Africa for the transmission and transportation of mining materials.

Flame-retardant conveyor belts, also known as whole-core flame-retardant conveyor belts, are made of an integral belt core that is impregnated with polyvinyl chloride impregnated paste and then plasticized or vulcanized.

It has the characteristics of high strength, large transportation capacity, and balanced transportation. At the same time, this product It has good flame retardant, antistatic, impact resistance, wear resistance, corrosion resistance and other properties. This product is mainly suitable for underground transportation in coal mines, and can also be used for material transportation in the metallurgical and chemical industries.

According to the temperature, the surface structure shape, viscosity and other parameters of the transported materials that transported by the flame retardant conveyor belt to select the type of the conveyor belt. The surface temperature is closely related to the using life of the flame retardant conveyor belt will directly affect the adhesive strength between the covered glue and the core layer, the wear resistance of the covered glue, crack resistance. Should be fully investigating and measuring the surface temperature and other using conditions that to choose the type of the flame retardant conveyor belt.

Relatively thick covered glue is an important condition to make sure that the tape with a long using life. The surface temperature of the whole conveyor belt should be measured, recorded and monitored continuously and uninterrupted, to avoid the unnecessary increasing temperature. For the tape that transport the high temperature materials is forced to cool, use water to cool the composite layer. Keeping the transported materials that distributed evenly based on the belt width without being too much concentrated. Prevent polluting from various oil to the conveyor belt, the damage to the belt by a trace mount of oil in the cooling water exceeds the damage caused by the heat of materials to the conveyor belt.

Once the belt containing hot materials stops running operation measures should be taken quickly that is remove the hot materials and apply the hot vulcanized joint. It can withstand a temperature that less than 150℃, the high temperature resistant type can withstand a temperature that less than 180℃, the burn resistant conveyor belt is able to transport the materials with the temperature between 200℃-600℃ that is suitable for transporting the sintered products, cement. Transportation of clinker and all kinds of high temperature materials in the mining, coke, building construction and casting industries.

There are some standards for the appearance quality problem of the flame retardant conveyor belt, the chemical industry standard is HG 2297-92 stipulate the appearance quality should comply with the appearance quality regulations of GB 526 fabric core conveyor belts. Therefore the conveyor belt has to meet the appearance quality standard of GB 526. Different types of raw rubber produce different quality and appearance of conveyor belts.