The key of installing heat resistant conveyor belt

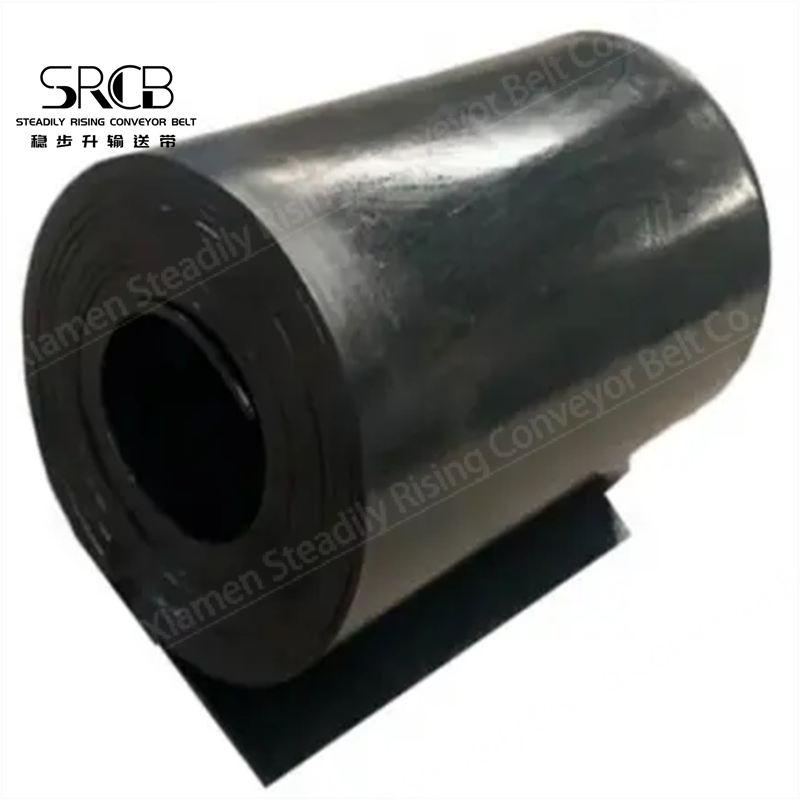

2024-03-14 00:36We shipped a super heat-resistant conveyor belt to Uganda. It is 105m long and 1600cm wide and it can resist 200 °C - 800°C. This heat-resistant conveyor belt is used in cement plant to conveyor clinker.

Heat resistant conveyor belt is a kind of conveying equipment that could work under a high temperature environment. It is widely used in steel, chemical, electric power, coal mine and other industries. Installing the heat resistant conveyor belt properly has importance influence for operating correctly and the using life. We will introduce the correct installation from the prepare working, installation steps of the heat resistant conveyor belt and the precautions.

1. Preparation. 1. prepare the tools and the materials in need, such as jacks, welders, wrenches, screwdrivers, screws, etc. 2. According to the size and length of the heat-resistant conveyor belt to prepare the appropriate working plants and shelves. 3. cleaning the installation site to ensure the ground is flat and free of oil and debris.

2. Installation methods. 1.Cleaning the dust and the debris on the conveyor body and check all of the parts of the conveyor are intact. 2. Spread the heat resistant conveyor belt on the ground to make sure that the size and the width is appropriately. 3.Using the jacks to life the conveyor bracket to the installation height and secure it stably. 4. pass the heat resistant conveyor belt through the roller one by one, place it along the transmission direction of the conveyor belt and tighten it. 5. Adjust the tension and the level of the conveyor belt appropriately according to the form and specifications of the conveyor belt. 6.using the electric welder to connect the joints of the conveyor belts to ensure the joint is firm. 7. installing the drive equipment and the eccentric, according to the positioning and adjusting as you need. 8.Connecting the conveyor belt with other parts of conveyor, such as guide, rollers, idlers, etc., 9. Checking whether all of the connections parts are tight and whether all of the drive equipment can work normally or not. 10. Turn on the power supply of the conveyor belt and perform a test run to check the running statues and transmission effect of the conveyor belt.

3. Things to note. 1. before performing installation operations, it is necessary to make sure that the installer have enough sense of security and knowledge, be familiar with the installation process and the operating specifications. 2. during the installation should pay attention to follow relevant specifications and operation guidelines. 3. When laying the heat resistant conveyor belt should notice the direction and the position ensure the conveyor belt could operate normally and service life. 4. At the joint of during connecting the joints with conveyor belt should check clearly the quality of the welding and the firmness to avoid the accident caused by loose the joints. 5. When install and adjust the tension of the conveyor belt should refer some relevant standards and specifications to avoid over-tightening or too loose tension. 6. before reforming, we should check the whole installation quality and the accuracy of the conveyor belt to ensure all of the parts can work together. 7. Regularly check and maintenance keep the conveyor belt and the conveyor body at a good condition to extend the using life.