The different structure design between flame retardant conveyor belt and ordinary conveyor belt

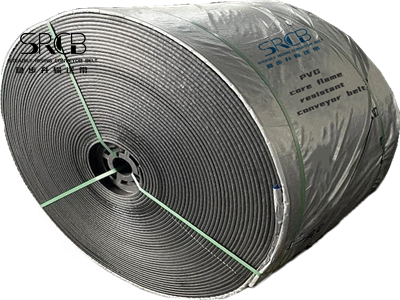

2024-03-15 00:11Last year, our company shipped an 85-meter flame-retardant conveyor belt with a bandwidth of 1400mm to a coal mine in Honduras for the transmission and transportation of mining materials.

Flame-retardant conveyor belts, also known as whole-core flame-retardant conveyor belts, are made of an integral belt core that is impregnated with polyvinyl chloride impregnated paste and then plasticized or vulcanized. It has the characteristics of high strength, large transportation capacity, and balanced transportation. At the same time, this product It has good flame retardant, antistatic, impact resistance, wear resistance, corrosion resistance and other properties. It is suitable for sites with flame retardant requirements. It is mostly suitable for mines and other flammable and explosive places, underground transportation of coal mines, and can also be used for material transportation in the metallurgical and chemical industries.

There some difference structure and the material between Flame retardant conveyor belt and the ordinary conveyor belt. The main difference is the flame retardant conveyor belt has the flame retardant properties to reduce the risk of fire and protect personnel and equipment.

Firstly, the material of flame retardant conveyor belt is different from the ordinary conveyor belt. Flame retardant conveyor belt usually use materials with flame retardant performance. Such as the material with fluorine-containing, high temperature resistant rubber, etc., These materials with flame retardancy, high temperature resistance, wear resistance and abrasion resistance, which can reduce the risk of fire.

Secondly, in the structure the flame retardant conveyor belt usually adopts multi layer structure, which has higher anti tensile strength and anti wear resistance. Special structure design make the flame retardant conveyor belt has longer using life and good capacity of loading. Ordinary conveyor belt usually adopts single-layer structure the anti tensile strength and the anti wear resistance is relevant poor.

Thirdly, flame retardant conveyor belt has special processed in the process in order to make its surface become more smoother also reduce the dust accumulation and reduce the risk of fire. The process of the ordinary conveyor belt is relatively simple and the surface is not enough smooth, flat, dust accumulation too much which easily lead to fire.

In addition, during the operation of the flame retardant usually equipped the special flame retardant equipment such as temperature detectors, flame detectors, detect the abnormal situations and take corresponding measures in time. However, ordinary conveyor belt doesn’t have these special safety equipment and it is hard to find and deal with the fire hazards in time.

In contrast, flame retardant has higher stability performance and it is able to reduce the occurrence of fire. In some places with high risk of fire such as mine, power plants, ports, etc., Flame retardant conveyor belt is widely used to transport the material that flammable and explosive and protect personnel and equipment.

However, flame conveyor belt have some restrictions. First, the cost of flame retardant conveyor belt is relatively high, the manufacturing cost of ordinary conveyor belt is lower so choose the ordinary conveyor belt will save the Special structure design make the flame retardant conveyor belt has longer using life and good capacity of loading cost in some place that doesn’t require so much. Secondly, the performance of the flame retardant conveyor belt will decline after a long time of using and it need regular testing and maintenance which increasing the management and maintenance.