The difference between flame retardant conveyor belt and nylon conveyor belt

2024-08-01 15:59In June 2021, our company shipped a 100-meter flame-retardant conveyor belt with a width of 1200mm to a chemical plant in Russia for the transmission and delivery of fuel.

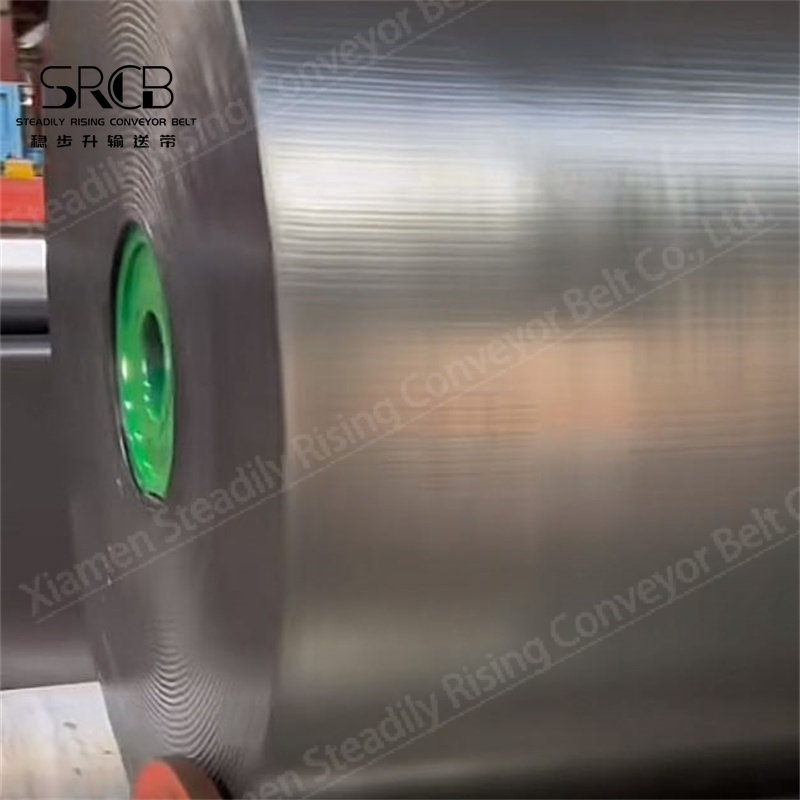

Flame-retardant conveyor belts, also known as whole-core flame-retardant conveyor belts, are made of an integral belt core that is impregnated with polyvinyl chloride impregnated paste and then plasticized or vulcanized.

It has the characteristics of high strength, large transportation capacity, and balanced transportation.

At the same time, this product It has good flame retardant, antistatic, impact resistance, wear resistance, corrosion resistance and other properties. This product is mainly suitable for underground transportation in coal mines, and can also be used for material transportation in the metallurgical and chemical industries.

Flame resistant conveyor belt and nylon conveyor belt are two different types of conveyor belt that used commonly in modern industry. Although their physical forms are very similar, they have lots of difference. The following will compare them from multiple dimensions and explain their difference to know their respective characteristics better.

1. Different materials

The materials of flame retardant conveyor belt and nylon conveyor belt are different. Flame retardant conveyor belt is made of rubber materials and flame retardants, which has flame retardant effect that could effectively reduce the risk of fire occurrence. But, nylon conveyor belt is made of other various materials, light weight and higher tensile strength.

2. Different uses

Flame retardant conveyor belt has a widely application range, suits for some special working condition spaces where with high temperature, humidity. Such as coal mine, chemical industry, building construction, metallurgical and other industries. Nylon conveyor belts mainly used in medium, low speed, medium, low loads occasions, such as logistics, food process, light industry and other applications fields.

3. Difference in wear and tensile strength characteristics

Nylon conveyor belt is consisted of a variety of materials, with good wear resistance and tensile strength so the using life would be longer. However, flame retardant conveyor belt is relatively fragile, is prone to be affected by chemical substance, temperature changed and other factors, with shorter using life.

4. Different price

The material cost of nylon conveyor belt is lower than flame retardant conveyor belt, so the price is relatively low. Because of flame retardant conveyor belt applied special materials, cost is relatively high, using value is high, thus the price would be expensive.

5. Different maintenance

Flame retardant conveyor belt applied special materials are relatively fragile, so need to be maintained more seriously and carefully to extend its using life. Nylon conveyor belt is relatively durable, hence its maintenance work is simple.

In short, there are some significant difference between the flame retardant conveyor belt and nylon conveyor belt in terms of material, application range, wear resistance, price, safety and many other aspects. Need to choose appropriate conveyor belt according to the actual needs to meet the production and transportation requirements.