Problems that easily occurred on the heat resistant conveyor belt

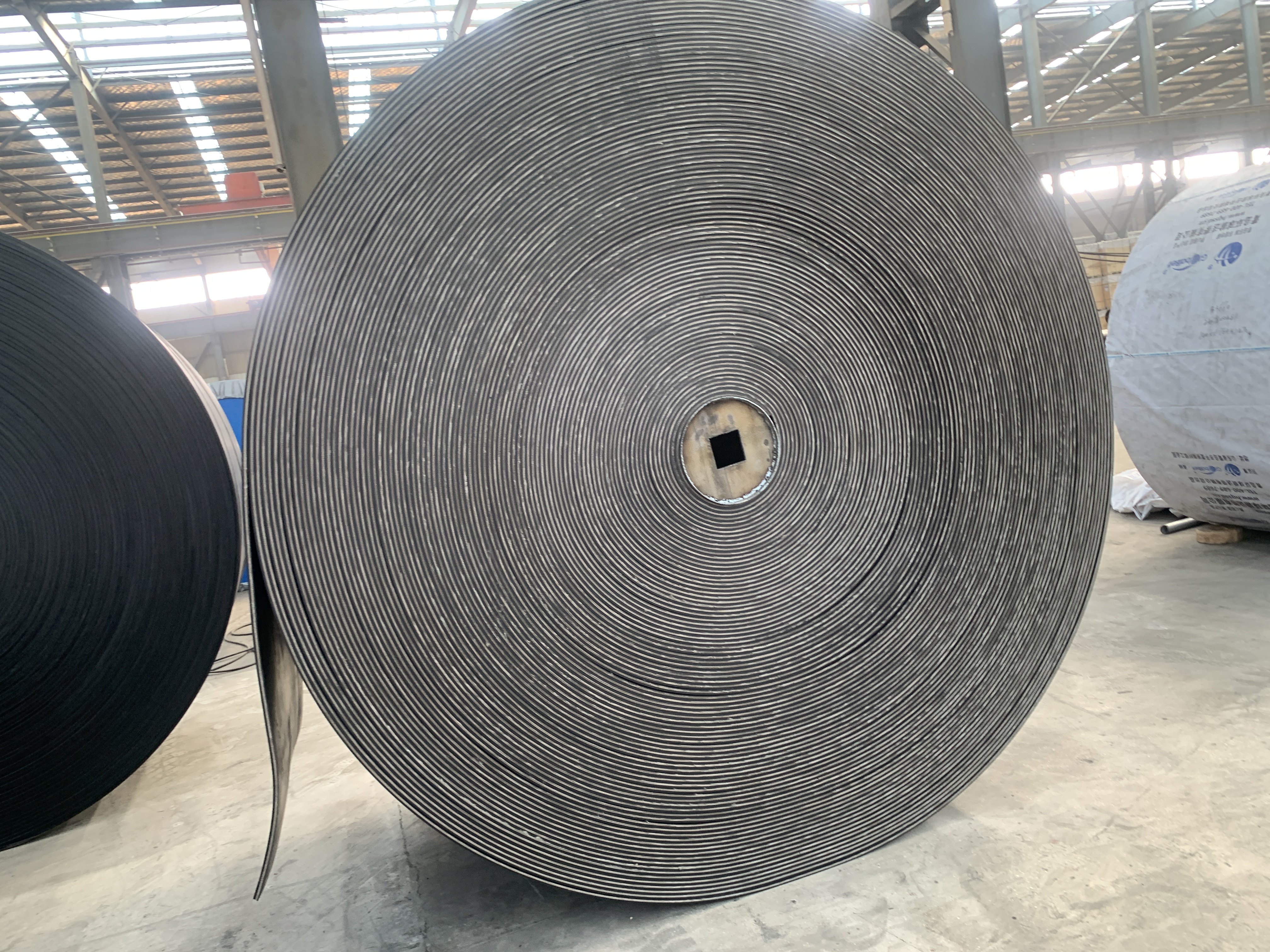

2024-06-24 16:09In June 2021, our company shipped a 97-meter heat-resistant conveyor belt with a bandwidth of 1200mm to a cement plant in Lebanon for the transportation and delivery of cement.

The heat-resistant conveyor belt is made of multi-layer rubber cotton canvas (polyester cotton cloth) or polyester canvas covered with high temperature resistant or heat-resistant rubber, and is vulcanized and bonded together at high temperature.

It is suitable for conveying hot coke below 175℃. Cement, slag and hot castings, etc.

It is mainly used in metallurgy, construction and other industries to transport high-temperature materials such as sinter, coke, cement clinker, etc. The material temperature does not exceed 800°C and the belt surface temperature does not exceed 220°C.

Heat resistant ordinary conveyor belt is a special conveyor belt that used for materials transportation under a high temperature ambient. It is usually be consisted with rubber, polyester fiber, nylon or glass fiber and other materials. With good heat resistant performance. However, during the using period, heat resistant ordinary conveyor belt might occurred some problems, the following will introduce some common problems and the corresponding solutions.

1. Temperature influence: Heat resistant ordinary conveyor belt is likely to be affected by the temperature. Leading to adhesive gelatinization, loosening or rupture. The solution is to choose a heat resistant ordinary conveyor belt with a suitable temperature and make sure its heat resistant performance could meet the actual working condition.

2. Performance degradation: The friction under a long time high temperature could cause surface damage to the heat-resistant ordinary conveyor belt., degrade its wear resistance performance. Solution is inspect regularly and replace the severely worn conveyor belts and reinforced lubrication and maintenance to reduce friction.

3. Shear rupture: under the high temperature condition, heat resistant ordinary conveyor belt is prone to shear rupture phenomenon resulting in leakage of materials and loss. Solution is to increase the width of the conveyor belt and apply in suitable joint to improve its entire strength and connectivity.

4. Deformation and fracture: Under the high temperature, material of heat resistant ordinary conveyor belt is easy to be deformation and breakage, affecting the normal operation. Solution is choose the appropriate heat resistant materials to make sure the conveyor belt has enough strength and durability. To avoid excessive materials impact and excessive stretching.

5. Electrical problems: In the high temperature ambient, electrical failures may cause fire hazard and other safety problems. Hence, should be inspected regularly and maintained the electrical equipment on the conveyor belt to ensure it could operate normally and take the appropriate fire prevention measurements.

6. Cleaning problems: Materials might be attached to the surface of heat resistant ordinary conveyor belt in the high temperature. Leading to it is difficult to cleaning. Solution is cleaning the conveyor belt regularly with using suitable cleaning agents and tools, to ensure the surface of conveyor belt is clean and no pollution.

7. Chemical resistance performance: some materials might contain acid and alkali and other chemical media which will lead to corrosion or damage to heat resistant ordinary conveyor belt. Therefore, should be according to actual condition to choose the conveyor belt with excellent chemical performance and take corresponding protection measurements.