How to select the heat resistant conveyor belt properly

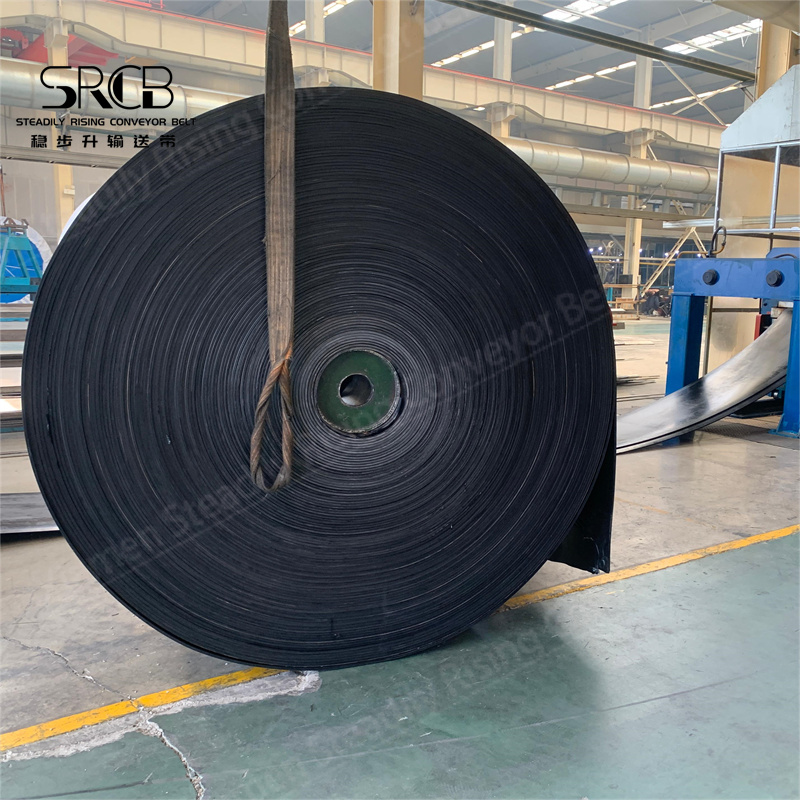

2024-04-01 14:57In November last year, our company shipped a 66-meter, 1200mm wide heat-resistant conveyor belt to a coal mine in Kazakhstan for the transmission and transportation of mineral materials.The heat-resistant conveyor belt is made of multi-layer rubber cotton canvas (polyester cotton cloth) or polyester canvas covered with high temperature resistant or heat-resistant rubber, and is vulcanized and bonded together at high temperature. It is suitable for conveying hot coke below 175℃. Cement, slag and hot castings, etc.

It is mainly used in metallurgy, construction and other industries to transport high-temperature materials such as sinter, coke, cement clinker, etc. The material temperature does not exceed 800°C and the belt surface temperature does not exceed 220°C.

Selecting the heat resistant conveyor belt is according to the specific working environment and the requirements to decide, the following advice of how to choose the appropriate heat resistance conveyor belt.

Firstly, the temperature of operating environment need to be considered. The main property of heat resistant conveyor belt is to operate normally under a high temperature environment, furthermore, the primary task is to make sure the temperature range in the working environment. In general, the temperature range of operating will be marked in technical documents in advance, according to whether the working temperature is in the range and can initially judge whether the heat conveyor belt is suitable or not.

Secondly, the property of the transported materials need to be considered. Different materials require different to the heat resistant conveyor belt. If the transported materials are sticky, then need to choose the heat resistance conveyor belt with oil resistance,wear resistance; if the conveyed materials are corrosive, you need to choose the heat resistant conveyor belt with acid and alkali resistance. Besides, the particle size, humidity and other factors that causing the impact to the conveyor belts need to be considered.

Again, the structure and the material of the conveyor belt need to be considered. Choosing the appropriate material and structure is the key to make sure that the heat resistant conveyor belt can operate normally under a high temperature environment. Generally speaking, the materials that could be selected are rubber, polyesters, fiberglass of the heat resistant conveyor belt, every materials have its advantages and the appropriate range. Moreover, need to notice whether the structure of conveyor belt is reasonable or not, whether it could resist the thermal expansion and the tension under a high temperature.

Furthermore,the using life of the heat resistant conveyor belt need to be considered. The service life of the heat resistant conveyor belt will directly affect the operational stability and the cost effectiveness during the working time. Hence, when selecting the heat resistant conveyor belt need to choose the products with reliable quality, long service life. At the same time, need to consider the performance of the conveyor belt such as fire resistance, anti static performance and etc. To make sure the reliability during using.

Also, need to consider the economics. The price, cost of maintenance and the environmental performance of the heat resistant conveyor belt will related directly to the operational efficiency and the image of the company. Thus, when selecting the heat resistant conveyor belt not only think about the performance and the quality need to be considered but also compares the different brand of products and the types of the products, choosing the most cost-effectively products.