How to choose the hot vulcanized materials of steel cord conveyor belt

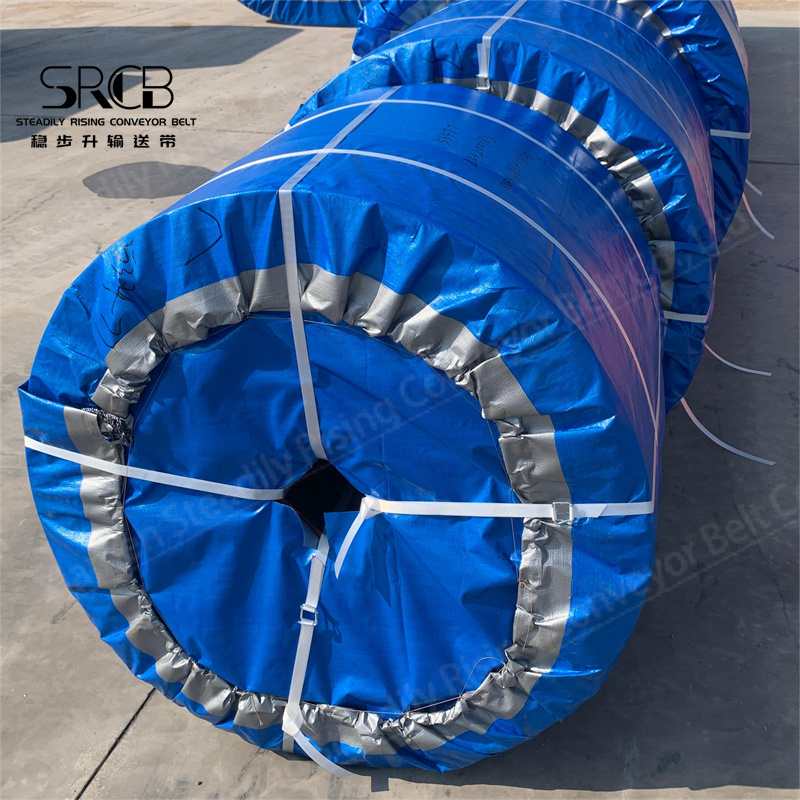

2024-05-19 16:36At the end of June last year, our company shipped a 30-meter steel wire conveyor with a bandwidth of 1200mm to a coal mine in North Africa for the transmission and transportation of mining materials.

The steel wire conveyor belt is a rubber conveyor belt with steel wire as the skeleton. It has the advantages of high tensile strength, good impact resistance, long service life, small elongation in use, good groove formation, and good flexibility resistance. It is suitable for conveying materials over long distances, large distances, and high speeds.

This product is composed of core glue, steel wire rope, covering layer and edge glue.

Wire rope conveyor belts are suitable for material transportation under tear-proof conditions in coal mines, mines, ports, electric power, metallurgy, building materials and other industries. They can be used for long-distance, large-span, large-volume and high-speed material transportation.

As we all know that heat resistant conveyor belt is consisted of core rubber, steel wire rope, covered layer and edge rubber which with skeleton as the rubber conveyor belt. The belt body with high tensile strength, using elongation is small, is suitable for long distance, large span, high speed of transporting materials. The joint of conveyor belt is the most technological complex of all the conveyor belt joints. It not only has the relatively complicated technology and its designed size number of joint parameter are the largest. Different levels of products are selected different joint structures.

In addition to the high requirement of operation process, the selection of materials is also important, select several thick of core glues(middle cushion glues), several thick conveying glues, how many layers need to be laid. Hot vulcanized joints are generally made of hot vulcanized glue, RIT unvulcanized glue and RIT unvulcanized top glue are operated under the temperature and pressure of vulcanizer. Among the hot vulcanized glue is responsible for the bonding with the conveyor belt, core rubber and top rubber. The core rubber also called middle rubber that used for improving the joint strength in the middle layer of conveyor belt. Surface glue is used to upper and lower layer that need to pay more attention to the anti slip and wear resistance.

During on site operation, need to use the layered peeling hook and a vise to peel off the belt and steel wire belt, and then polish the joints. After polishing, use the cleaning agent to deeply cleanse the impurities and oil stains on the surface of the conveyor belt, apply hot vulcanized glue SK823 on the steel wire belt and the bonding parts of the core glue and top glue; lay the core glue on the surface of the steel wire rope. For the outer layer of core rubber the specific number of layers depends on the specification and the requirements of the conveyor belt.

Checking the installation of the vulcanizer is correct and the wiring is correct. Connect the temperature sensor plug in the metal thermometer if necessary, turn on the vulcanizer control switch power supply and start heating and vulcanization. When the timer expires, the vulcanization switch automatically trips. Once everything is fine, you can lock the switch and remove the temperature sensor. Connect the cooling water pipe and start pouring water into the heating plate for cooling. When the temperature drops below 80°C the pressure can be released, the vulcanized plate can be taken out and vulcanization is completed.

After taking the vulcanized board, check whether the joint vulcanization quality meets the requirements and if there are any defects and repair and trim them immediately to make edges neat and smooth, no more defects and excess rubber. If find a bulge, prick it immediately with an awl to prevent the bulge from expanding.