Flame-retardant conveyor belt

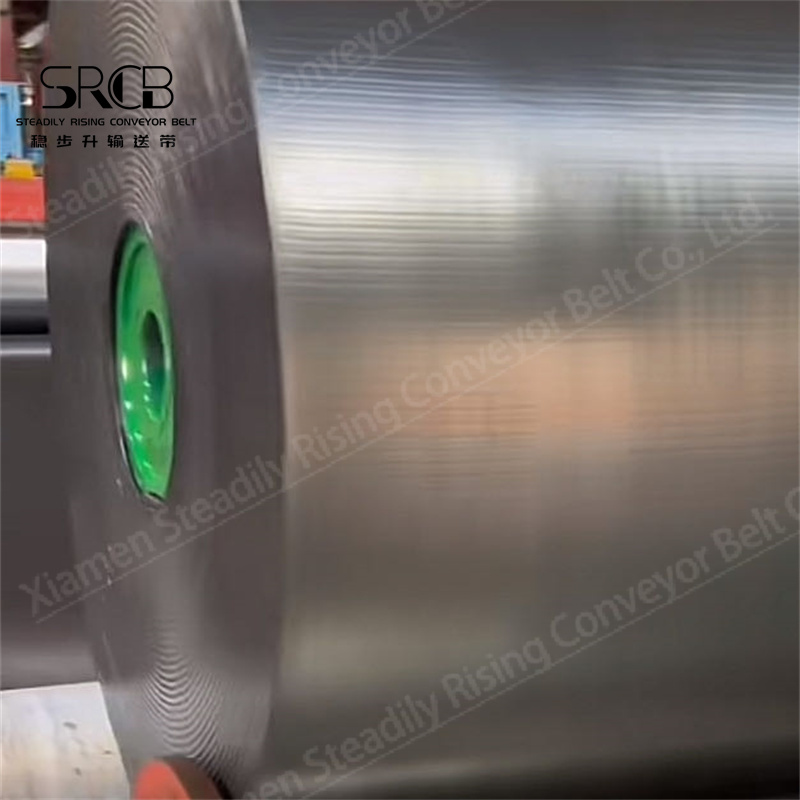

2024-03-06 10:25Last year, our company shipped a 70-meter flame-retardant conveyor belt with a bandwidth of 1200mm to a coal mine in the United States for the transmission and transportation of mining materials.

The flame-retardant conveyor belt is also called a whole-core flame-retardant conveyor belt. It is made of an integral belt core that is impregnated with polyvinyl chloride paste and then plasticized or vulcanized. It has the characteristics of high strength, large transportation capacity, and balanced transportation. At the same time, the product has good flame retardancy, antistatic, impact resistance, and wear resistance. , corrosion resistance and other properties.

This product is mainly suitable for underground transportation in coal mines, and can also be used for material transportation in the metallurgical and chemical industries.

Flame-retardant conveyor belt is a strip material that used for conveying and kinds of items, it can prevent the fire of spreading and has the fire of resistance. In order to prevent the spread of fire, flame-retardant conveyor belt should has the following aspects of fire-retardant measures.

Firstly, the flame-retardant conveyor belt need to be selected a material that with good fire-retardant to be made of. There are three common fire-retardant materials which are named chlorinated polyethylene (PVC), ethylene polypropylene (EPP) and spandex. When these materials faced the fire they can absorb the energy quickly and stop the spread of fire, preventing the fire of spread and occurrence.

Secondly, the structure of fire-retardant conveyor belt should be designed properly to enhance the capacity of fire-retardant. Usually, the upper surface of fire-retardant conveyor belt need to be applied by fire-retardant materials such as silicon tape to prevent the fire from touching the surface of the conveyor belt directly. At the same time, the back surface of the conveyor belt should be made of good thermal insulation properties, to avoid the heat conducted form the back to the surface. Isolating the heat source and prevent the fire spread into the interior of the conveyor belt.

Thirdly, the key of preventing spread the fire is install the fire-retardant and maintenance. During the installation, we should ensure there are enough space between the conveyor belt and the fixed equipment to avoid the friction of fire to arouse the fire. What’s more, the joint of conveyor belt should be firm and reliable and mustn’t be loose to prevent the heat source get into the interior of conveyor belt. In daily maintenance, we should check whether the surface of the conveyor belt get damaged and the cracks or not regularly. And replace them or repair them in time.

In addition, we can enhance the capacity of fire-retardant of the conveyor belt with a series of fire detection and extinguishing equipment. Such as, we can set up the smoke detectors, flame detector and temperature detectors to detect the occurrence of fire in time. Also, we can through the automatic sprinkler systems and dry powder to extinguished the fire.